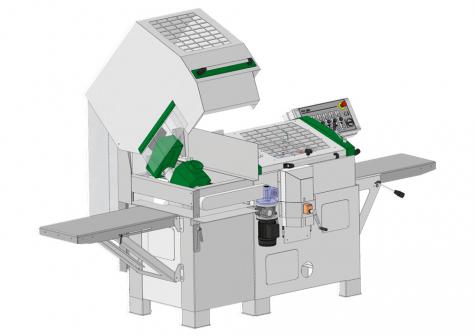

Logosol continues to be on the move, designing innovative solutions for planning/moulding challenges. When the PH360, Logosol’s largest four-sided planer/moulder, was first released, everyone noticed there was an extra button on the control panel of the PH360. Some people utilized it to control the external chip extractor. However, now the button’s real function is revealed, it’s to control an optional fifth cutter head.

Logosol strives to design modular machines, to allow for future development. The most developed along modular lines, for example, are the chainsaw powered sawmills. It’s fully possible to begin with the small handheld timber jig and develop it into a fully-equipped portable sawmill.

The PH360 is designed according to the same modular philosophy. It was equipped from the start for a fifth cutter head. The only thing that gives away the potential of this future option is an extra start button on the control panel. The development work has taken a little time, since it involves a brand new type of cutter head, with a func-tion not found on any other planer.

A TRUE MULTI-CUTTER

”The cutter is in principle an MF30 vertical milling machine,” reveals product manager Mattias Byström.

The milling unit is an independent unit that attaches to the planer, and the electrical systems are coupled together. Both machines function as a single unit, with the same feeding speed. All cutter heads are controlled from the PH360 control panel.

The MF30 model is a multi-machine in the widest sense of the word. The motor unit can be swivelled 270 degrees and the milling arbor can handle both a side cutter spindle of the same type as already fitted on the PH360 or a spindle into which router bits can be fitted. The machine can process timber from below, from the side and from above. With a fifth cutter head in a four-sided planer/moulder it becomes possible to produce very complicated details in a single operation.

”The PH360 with a fifth cutter head is a very efficient machine for producing windows, for example,” points out Mattias Byström.

The fifth cutter head is undergoing integration testing. No launch date has been set, but interested parties can get in touch with Logosol for further information about this unique option for the PH360.

EQUIPPED FOR MORE

The PH360 is also equipped for even more additional functions. Two are now available. The planer/moulders now supplied have a hole in the feeding table, for attaching a press roller to help guide the lumber before it enters the planer. The press roller is available for delivery.

A longer jointer fence is also available to order. This improves the function of the planer.